Medical

Metrology in the medical sector includes equipment such as CMMs, vision systems and equipment to measure roughness and form.

Requirements in the Medical Sector

In the medical sector as components can be implanted into the human body, parameters such as surface roughness, as well as form are critical.

Typical metrology products include.

- Alicona InfiniteFocus focus variation systems

- CMMs

- Vision measuring systems

- Profile measurement

In the medical products sector, the requirement for conformance and compliance is absolute as is the need to keep meticulous records of all activities and manufacturing processes.

The same strategies and processes need to apply to any measurement or inspection technology employed in the sector with IQ, PQ, OQ validation testing required for all new equipment installed in the industry.

Other Sectors

Manufacturing

Manufacturing requires extensive measuring equipment to assure quality and enhance productivity and compliance with specifications.

Tooling

Tooling manufacturing and the machine tool sectors are gaining substantial productivity benefits with measurement and scanning technologies.

Sheet Metal

Sheet metal products manufacturers need fast and reliable measurement. The Planar system is the fastest way to inspect 2D sheet metal parts.

Typical Applications

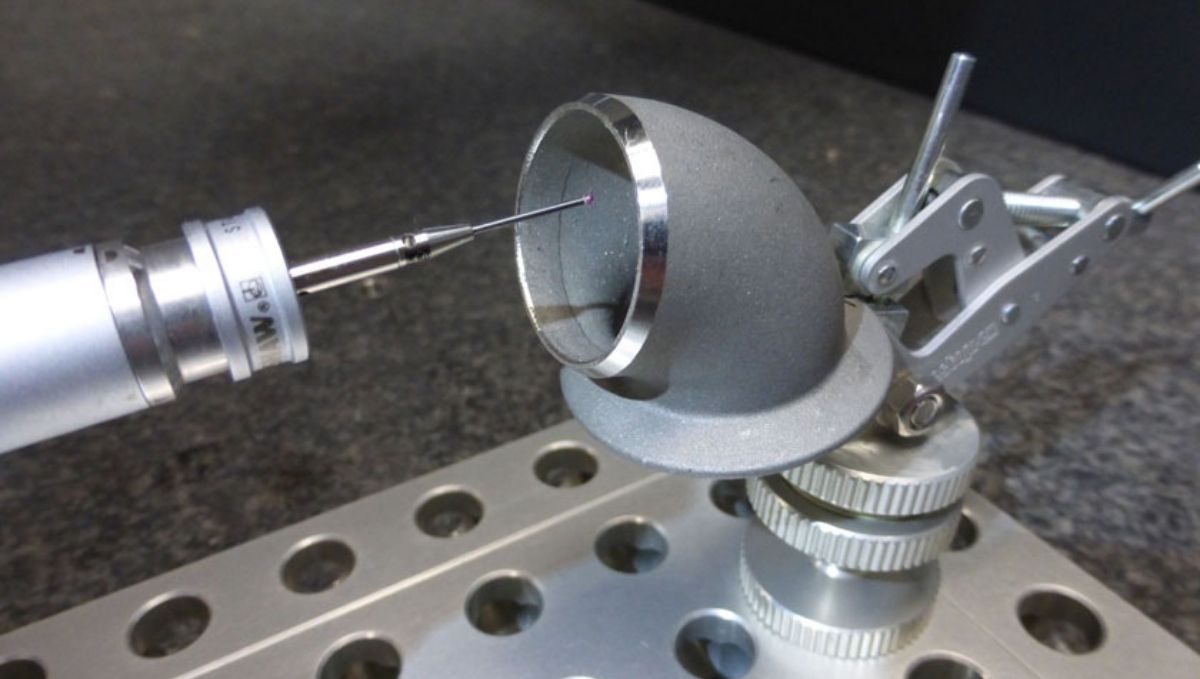

There are a number of applications in the medical sector where metrology systems play a key role. Here we discus a few of these.

Measurement of small and intricate components

In the medical products manufacturing field we have found the use of vision systems such as Starrett’s AVR300 CNC 300 x 200 mm vision system to be particularly popular in Australia and New Zealand.

This system with its M3 software is easy to operate and to write complex measurement routines to measure batches of parts. It fits in-between hand measuring tools used on the factory floor and CMMs which are used in the quality assurance Lab to measure complex components. The vision system can be operated with trained staff in order to produce highly accurate and repeatable measurement results for the manufactured product.

Testing of Closures and Packaging

We are finding that the new range of force testing systems from Starrett is being increasingly used by the medical components sector to check for the closure strength of packaging as well as to test and to measure peel strength of packs and of various medical devices as part of their regulatory requirements for testing and compliance.

Contact Us

For more information on any of our products or services or a quote, please complete the form below for a fast response.

Contact Info

Head Office

84 Hotham Street Preston VIC. 3072 Australia

Open Office Hours

M-F: 8am – 6pm

S-S: Closed

Get in Touch

metoptix.com.au

1300 363 409

Other Products

Structured light

hand-held scanners