4D InSpec Standard

4D InSpec Standard

Surface defect inspection technology from 4D Technology.

About 4D InSpec Standard

- Models: 4D InSpec Standard

- Services Provided: Full sales, spare parts and accessories, support, installation and training

- Applications and Uses: Ideal for workshops, machine shops and general industry.

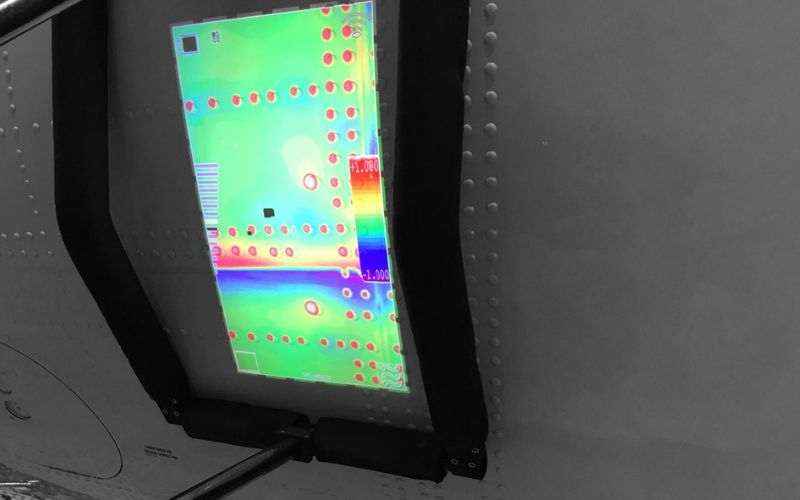

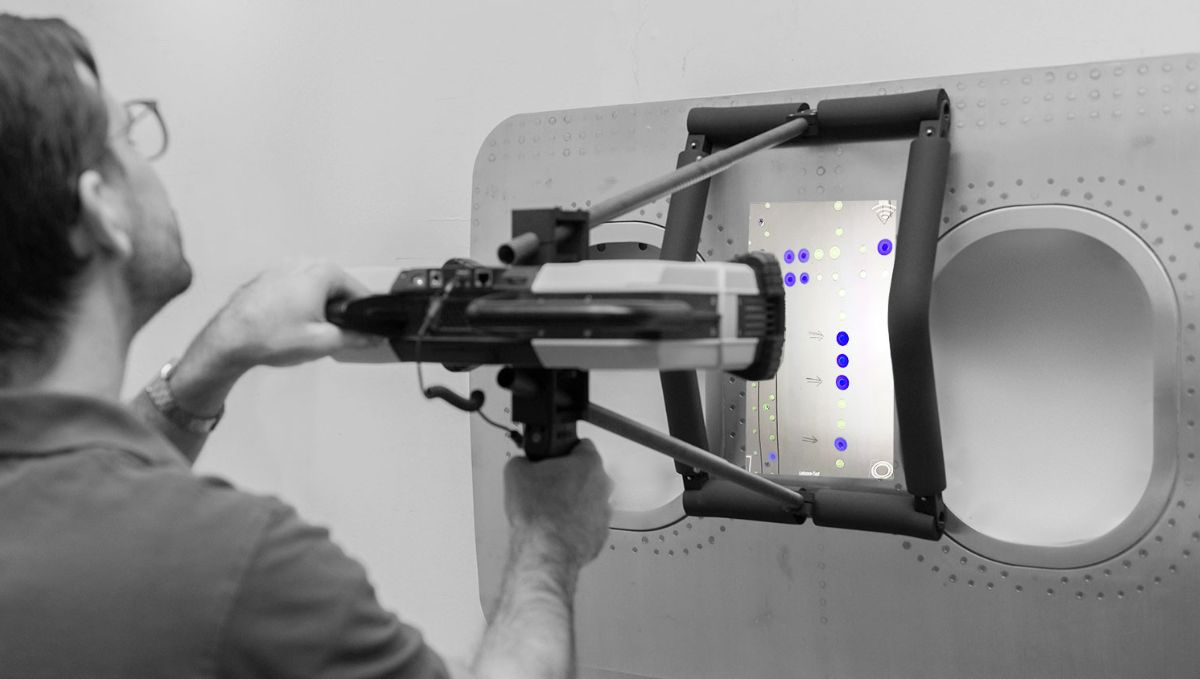

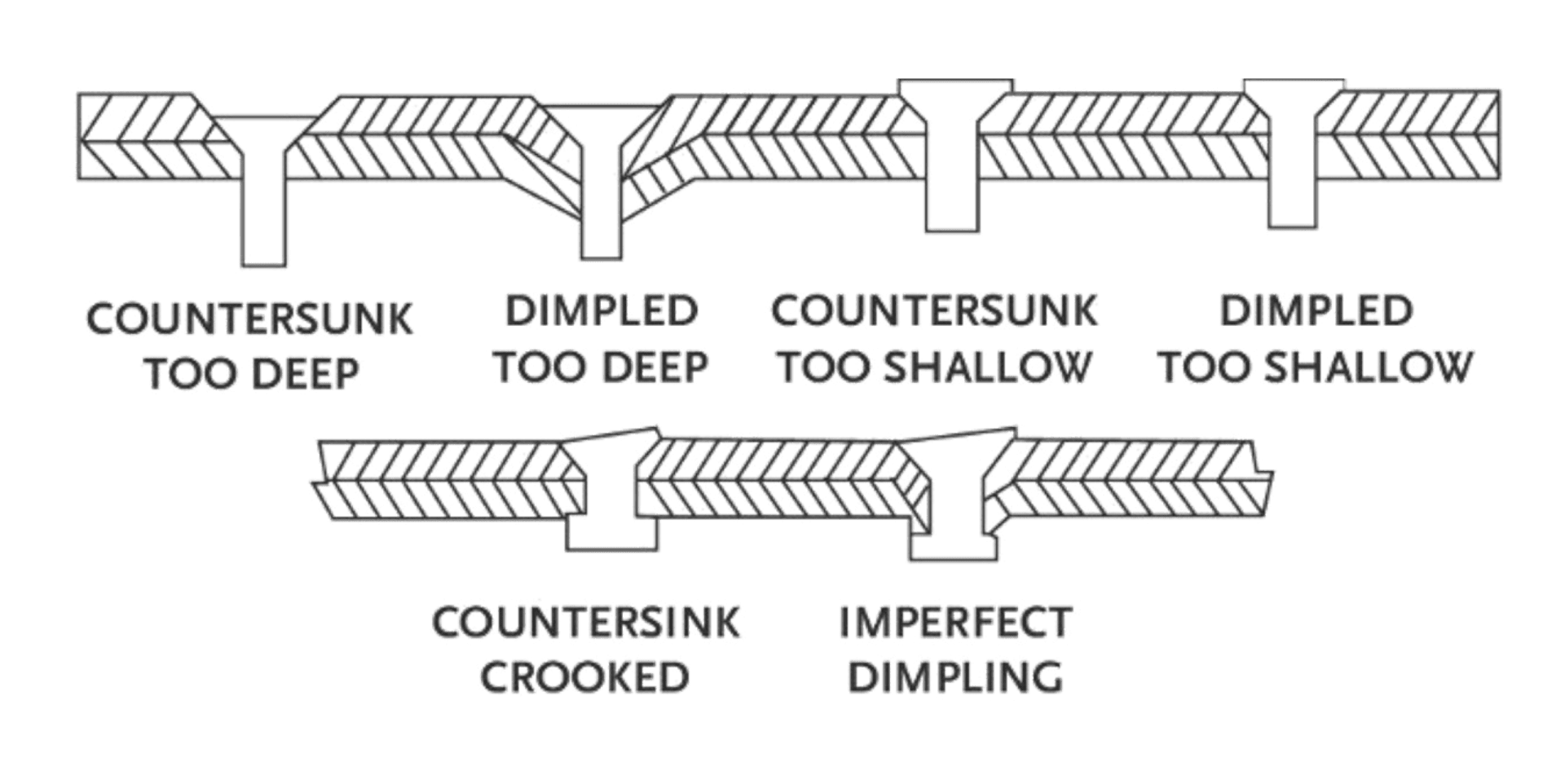

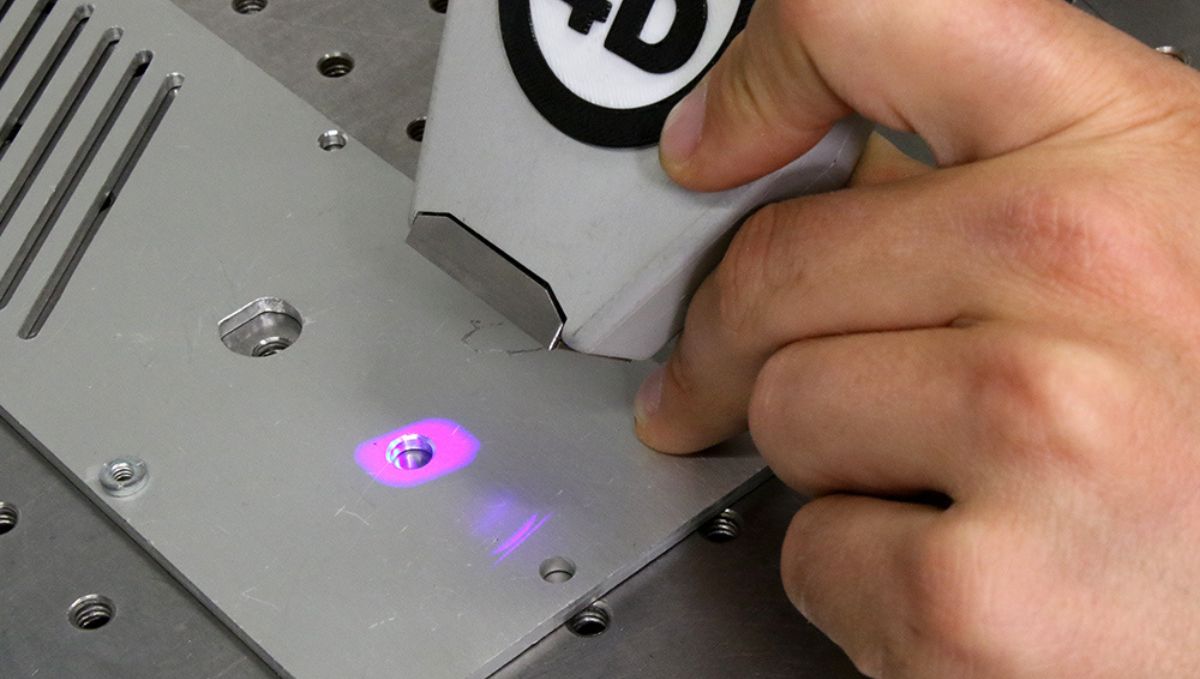

The 4D InSpec Standard system is a hand-held 3D scanner that uses polarized structured light technology and a camera to produce a dense 3D point cloud. By analysing the collected data with the 4D InSpec software, users can see the extent of the defect or damage and immediately quantify the size and depth and take any corrective action necessary.

The new edge break functionality of the system also allows manufacturers to accurately and importantly repeatably measure radii of edges on components for conformance to specifications.

Related Products

4D InSpec XL

The 4D InSpec XL system is a surface inspection tool for defects with a larger field-of-view, better resolution, and larger depth of focus than the standard system.

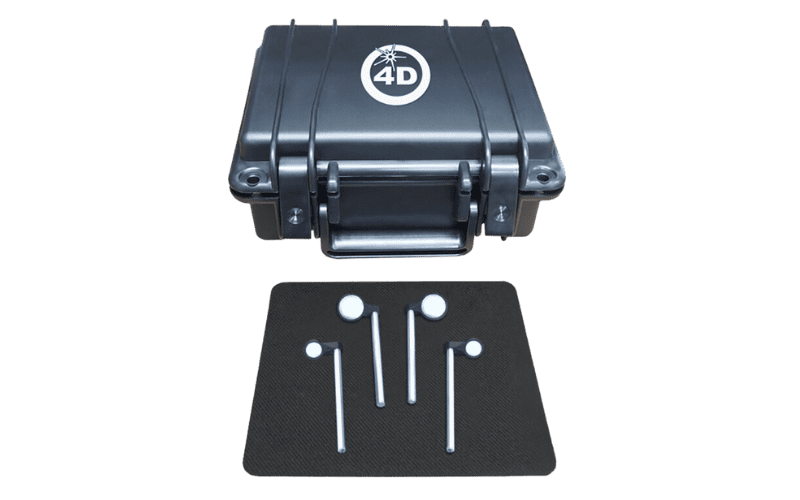

4D InSpec Accessories

A full range of accessories and options is available for the 4D InSpec systems.

Contact Us

For more information on our products or services or a quote, please complete the form below for a fast response.

Contact Info

Head Office

84 Hotham Street Preston VIC. 3072 Australia

Open Office Hours

M-F: 8am – 6pm

S-S: Closed

Get in Touch

metoptix.com.au

1300 363 409

Other Products

Structured light

hand-held scanners